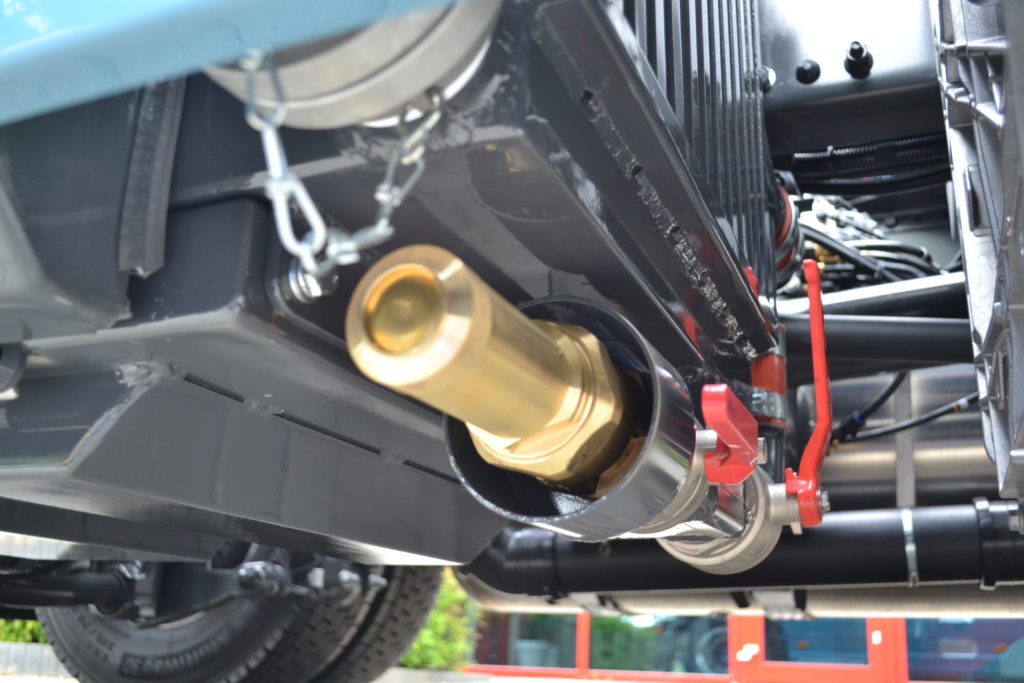

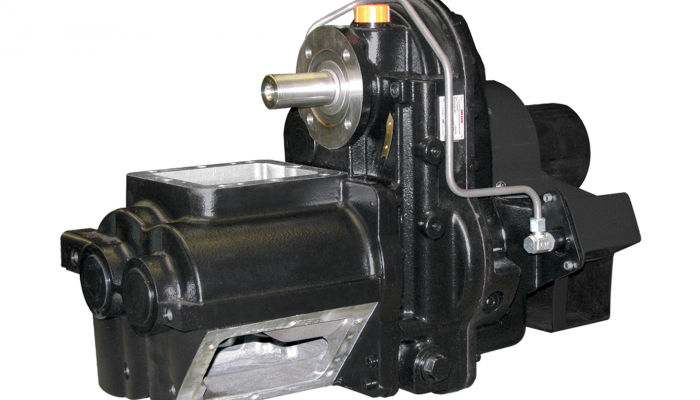

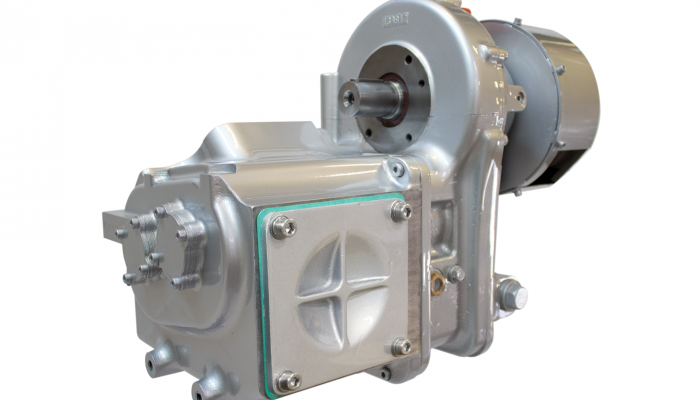

The direct driven installation is particularly suitable for semi-trailer trucks with a pusher axle. The position of the ingoing shaft of the compressor has a positive effect on the angle and length of the PTO-shaft length (length and angle of the PTO).

You can discuss the possibilities for mounting a compressor installation on a tractor with a pusher axle or an LNG or CNG installation with our specialists.