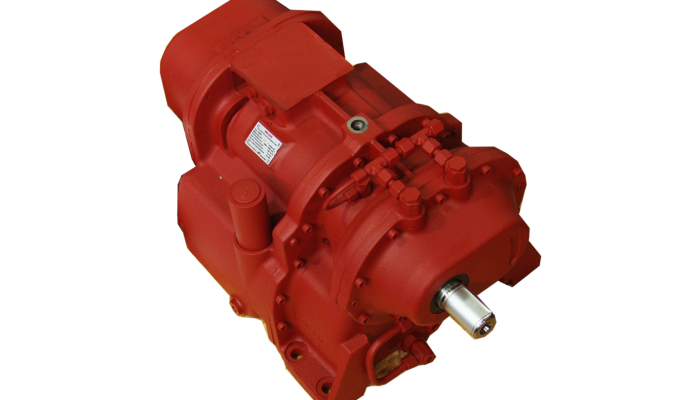

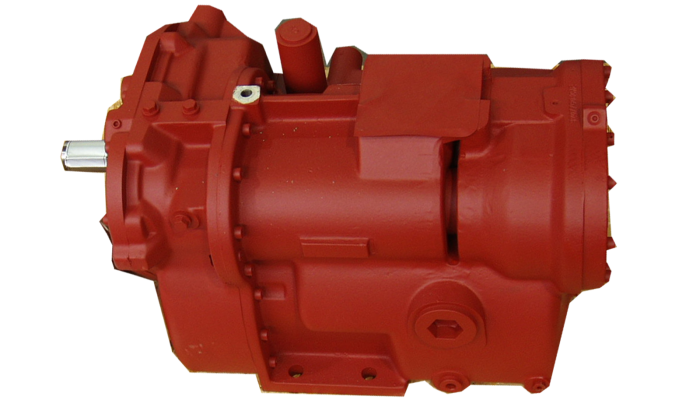

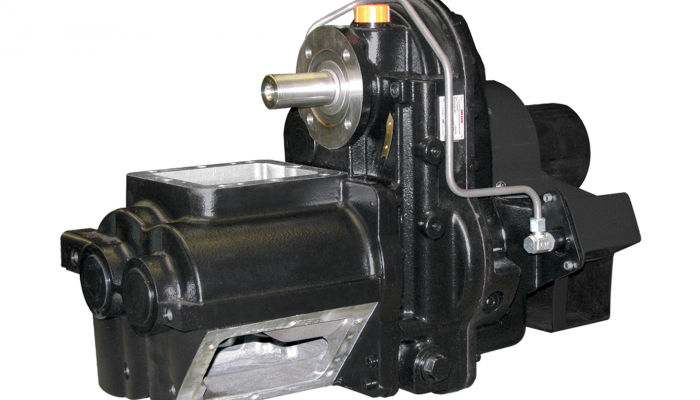

If a hydraulic drive system is used, the compressor can be placed anywhere on a tractor or trailer. Only high-quality components are installed in this installation due to the high load on the installation.

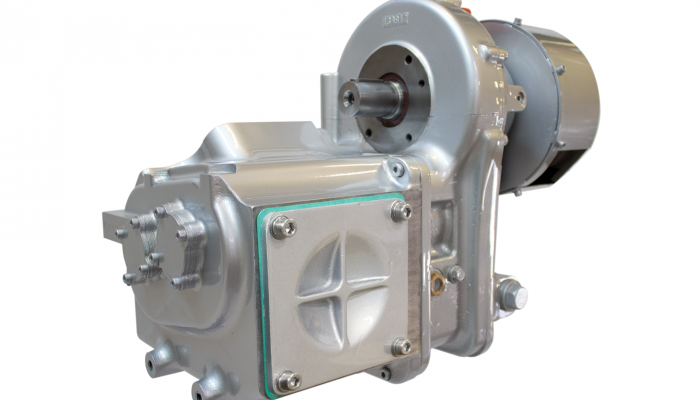

Hydraulic drive

The hydraulic motor is directly mounted onto the compressor using an adapter and a flexible connection. Moreover, the hydraulic pump is driven by a PTO on the gearbox. A HyDrive cools the oil. This was developed for maximum cooling at greater power. By using a hydraulic drive, the compressor installation can be mounted anywhere on a tractor or trailer, regardless of the PTO position.

Compressed air cooler

Air cooling is achieved by means of an aluminium fan. This allows for a very compact construction. A shut off delay ensures higher operational reliability.

Especially for combustible or temperature sensitive products the installation is equipped with a compressed air cooler. The compressed air cooler is completely made of aluminium and cools the compressed air approximately 100°C. Depending on intake temperature, pressure and capacity the outlet temperature is roughly 65°C.

Silencers and filter

The RTI/MMT aluminium pulsation silencer is constructed based on the volume size and is equipped with a (steered) pressure relief valve and a built in non-return valve.

The aluminium filter unit is equipped with a high-quality and moisture resistant 5 μm RTI/Mira air filter/intake silencer.

By applying these parts in combination with aluminium pipes and a cooling installation, the installation will meet all requirements set by the chemical and food industry.

OPTIONS

The RTI installation can be tailored to your wishes with several options and additions.

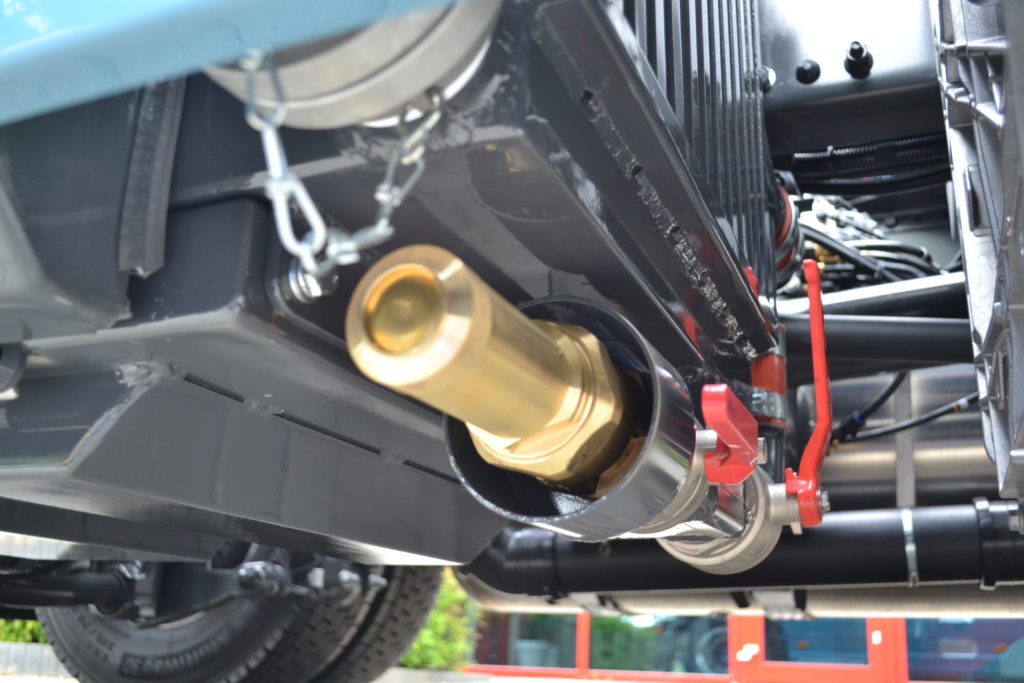

Rotary coupling

Specifically for feed there is the possibility of a rotary coupling in front of the fifth wheel hitch. By using a rotary coupling in front of the fifth wheel hitch the compressor hose can be connected to the semitrailer permanently.

High air intake

The compressor installation can be equipped with a high air intake developed by RTI. Air is drawn in at the top of the driver’s cab, this prevents the intake of dust and exhaust gasses.

The intake of cleaner and cooler air will increase the longevity of the air filter. The high air intake can also be adjusted to the Mobil Plastics requirements for air intake. (MP requirements state that air should be drawn in at the top of the driver’s cab.)

Air outlets

The standard outlets of an RTI installation are placed at the front of the cooler, the cold outlet at the top and the warm outlet at the bottom. You can also choose to have the outlets changed according to your wishes.

Compressed air cooler

To save space the compressed air cooler can be installed at the bottom of the installation. The minimum space required to mount the installation is 850 mm.

Other options

Flexible use of the installation can be attained by the following options:

- a blow-off silencer

- an extra pressure relief valve (high/low pressure)

- cold and warm air mixing

- a combination of the above

COMPRESSORS

ALFONS HAAR CMAX3

| Type | Alfons Haar Cmax3 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 625-1180 |

| Flow rate (m3/h) at 2 bar | 610-1070 |

| Flow rate (m3/h) at 2.5 bar | 605-1055 |

| Speed range (rpm) | 1200-2100 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 38-65 kW |

| Minimum mounting space | 100 cm |

| Soundlevel installation | 81 dBA (stationary unit 75 dBA) |

| Dimensions installation | 95x75x75 cm |

ALFONS HAAR CMAX2

| Type | Alfons Haar Cmax2 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 335-585 |

| Flow rate (m3/h) at 2 bar | 330-560 |

| Flow rate (m3/h) at 2.5 bar | 320-555 |

| Speed range (rpm) | 2100-3500 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 22-36 kW |

| Minimum mounting space | 75 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 70x68x70 cm |

CVS SiloKing 1100LS

| Type | CVS SiloKing 1100LS |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 505-995 |

| Flow rate (m3/h) at 2 bar | 490-980 |

| Flow rate (m3/h) at 2.5 bar | 475-962 |

| Speed range (rpm) | 1630-2930 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 28,5-52,5 kW |

| Minimum mounting space | 100 cm |

| Soundlevel installation | 81 dBA (stationary unit 75 dBA) |

| Dimensions installation | 95x75x75 cm |

CVS SiloKing 700

| Type | CVS SiloKing 700 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 395-610 |

| Flow rate (m3/h) at 2 bar | 385-600 |

| Flow rate (m3/h) at 2.5 bar | 376-587 |

| Speed range (rpm) | 2400-3600 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 22,5-33,5 kW |

| Minimum mounting space | 100 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 95x75x75 cm |

CVS SiloKing 1500

| Type | CVS SiloKing 1500 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 710-1580 |

| Flow rate (m3/h) at 2 bar | 690-1560 |

| Flow rate (m3/h) at 2.5 bar | 670-1540 |

| Speed range (rpm) | 1000-2000 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 41-85 kW |

| Minimum mounting space | 120 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 105x75x75 cm |

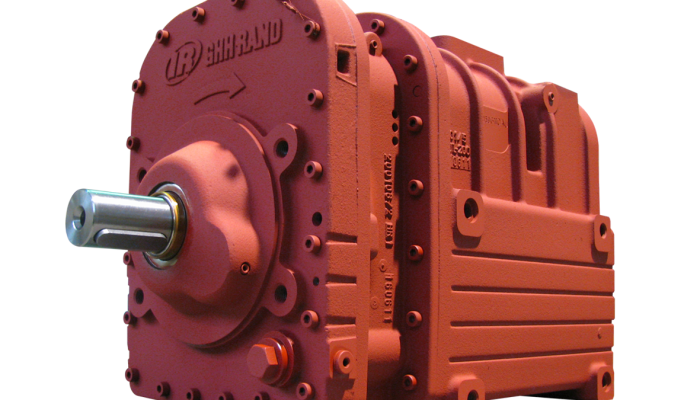

GHH CG80/h

| Type | GHH CG80/h |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 455-573 |

| Flow rate (m3/h) at 2 bar | 441-559 |

| Flow rate (m3/h) at 2.5 bar | 426-545 |

| Speed range (rpm) | 3000-3600 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 27,2-33,9 kW |

| Minimum mounting space | 100 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 95x75x75 cm |

GHH CS80/1

| Type | GHH CS80/1 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 304-730 |

| Flow rate (m3/h) at 2 bar | 290-718 |

| Flow rate (m3/h) at 2.5 bar | 498-706 |

| Speed range (rpm) | 1000-2000 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 19,9-41,4 kW |

| Minimum mounting space | 100 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 95x75x75 cm |

GHH CS85

| Type | GHH CS85 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 435-989 |

| Flow rate (m3/h) at 2 bar | 420-975 |

| Flow rate (m3/h) at 2.5 bar | 404-962 |

| Speed range (rpm) | 1000-2000 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 25,0-55,4 kW |

| Minimum mounting space | 100 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 95x75x75 cm |

BLACKMER TYPHON II 20R

| Type | Blackmer Typhon II 20R |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 530-1040 |

| Flow rate (m3/h) at 2 bar | 500-1010 |

| Flow rate (m3/h) at 2.5 bar | 750-1000 |

| Speed range (rpm) | 1200-2000 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 32,5-59 kW |

| Minimum mounting space | 100 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 95x75x75 cm |

KAESER OMEGA53P

| Type | Kaeser Omega53P |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 0.3 bar | 270-2458 |

| Flow rate (m3/h) at 1 bar | 570-2118 |

| Speed range (rpm) | 700-4200 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 1 bar |

| Power at coupling at 1 bar | 34-75 kW |

| Minimum mounting space | 120 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 109×69,5×70 cm |

GARDNER DENVER T5CDL9

| Type | Gardner Denver T5CDL9 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1 bar | 360-955 |

| Flow rate (m3/h) at 1.2 bar | 340-935 |

| Speed range (rpm) | 1000-2000 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 1,2 bar |

| Power at coupling at 1.2 bar | 18-36 kW |

| Minimum mounting space | 125 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 105x75x75 cm |

GARDNER DENVER T5CDL12

| Type | Gardner Denver T5CDL12 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1 bar | 490-1260 |

| Flow rate (m3/h) at 1.2 bar | 468-1233 |

| Speed range (rpm) | 1000-2000 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 1,2 bar |

| Power at coupling at 1.2 bar | 22-49 kW |

| Minimum mounting space | 125 cm |

| Soundlevel installation | 81 dBA |

| Dimensions installation | 105x75x75 cm |

ALFONS HAAR VMAX1

| Type | Alfons Haar Vmax1 |

|---|---|

| System | Vane |

| Flow rate (m3/h) at 1.5 bar | 90-165 |

| Flow rate (m3/h) at 2 bar | 85-150 |

| Flow rate (m3/h) at 2.5 bar | 75-135 |

| Possible discharge rate (I/min) at 2 bar | 850 |

| Speed range (rpm) | 1000-1600 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 6,5-10 kW |

| Minimum mounting space | 65 cm |

| Soundlevel installation | 84 dBA |

CVS RKL 160

| Type | CVS RKL 160 |

|---|---|

| System | Vane |

| Flow rate (m3/h) at 1.5 bar | 200-133 |

| Flow rate (m3/h) at 2 bar | 92-123 |

| Flow rate (m3/h) at 2.5 bar | 83-111 |

| Speed range (rpm) | 1200-1600 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 6,5-8,6 kW |

| Minimum mounting space | not applicable |

| Soundlevel installation | 84 dBA |

| Dimensions installation | not applicable |

GHH SV200

| Type | GHH SV200 |

|---|---|

| System | Vane |

| Flow rate (m3/h) at 1.5 bar | 75-163 |

| Flow rate (m3/h) at 2 bar | 65-152 |

| Flow rate (m3/h) at 2.5 bar | 55-140 |

| Speed range (rpm) | 1000-1800 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 6,0-11,3 kW |

| Minimum mounting space | not applicable |

| Soundlevel installation | 84 dBA |

| Dimensions installation | not applicable |

BLACKMER B600 20R

| Type | Blackmer B600 20R |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 270-540 |

| Flow rate (m3/h) at 2 bar | 250-520 |

| Flow rate (m3/h) at 2.5 bar | 360-500 |

| Speed range (rpm) | 1200-2000 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling | 17-35 kW |

| Minimum mounting space | not applicable |

| Soundlevel installation | 90 dBA |

| Dimensions installation | not applicable |

GHH CS1200

| Type | GHH CS1200 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 731-1141 |

| Flow rate (m3/h) at 2 bar | 714-1126 |

| Flow rate (m3/h) at 2.5 bar | 697-1110 |

| Speed range (rpm) | 1200-1800 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 39,3-61,9 kW |

| Minimum mounting space | 60 cm |

| Soundlevel installation | 85 dBA |

| Dimensions installation | 55x75x75 cm |

CVS SKL1200

| Type | CVS SKL1200 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 537-1096 |

| Flow rate (m3/h) at 2 bar | 504-1070 |

| Flow rate (m3/h) at 2.5 bar | 481-1045 |

| Speed range (rpm) | 1000 – 1800 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 31-57 kW |

| Minimum mounting space | 60 cm |

| Soundlevel installation | 85 dBA |

| Dimensions installation | 55x75x75 cm |

GHH CS750

| Type | GHH CS750 |

|---|---|

| System | Screw |

| Flow rate (m3/h) at 1.5 bar | 547-774 |

| Flow rate (m3/h) at 2 bar | 532-759 |

| Flow rate (m3/h) at 2.5 bar | 516-744 |

| Speed range (rpm) | 1350-1800 |

| Suction conditions | 1 bar-20 °C |

| Maximum pressure | 2,5 bar |

| Power at coupling at 2 bar | 31-42 kW |

| Minimum mounting space | 60 cm |

| Soundlevel installation | 85 dBA |

| Dimensions installation | 55x75x75 cm |